Description

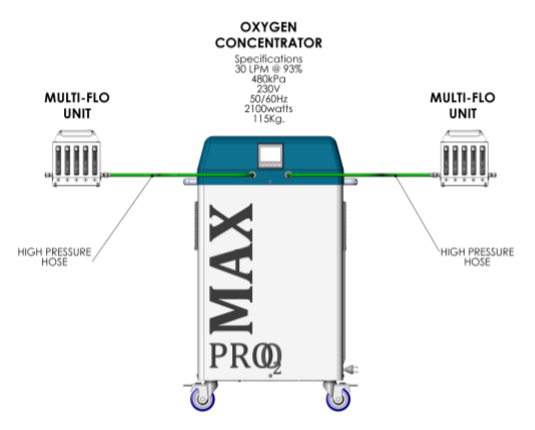

Nidek Max-30 Plant Oxygen Concentrator

– Up to 30 LPM Oxygen

– Ideal for Vets, Labs and Clinics

Features

The Max 30 oxygen concentrator provides up to 30 liters of oxygen per minute and is ideal for small hospitals, laboratories and veterinary clinics. It can also be used as a cylinder filling station or connected to anesthesia machines and ventilators. It is built on a reliable modular platform with a superior grade of molecular sieve.

Easy to use

Just connect to an electrical outlet, turn the Master Switch ON/OFF power switch

to the ON position and press the START button on the front display panel and set the

desired flow rate.

Dependable

Its internal air compressors, filtration system, molecular sieve, storage tanks and flow

control system are designed for 24/7 operation.

Durable

With oxygen-clean brass tubing and valves, the MAX 30 can operate even in

environments as described under the specifications page.

Safe

A built-in oxygen pressure regulator maintains oxygen outlet pressure at 50 psi (3.4 bar).

Each of the compressors on the MAX 30 has 0.38 hp and have a built-in safety relief

valve to prevent excessive pressures in each compressor.

Nidek Max-30 Plant Oxygen Concentrator Process Flow Description

Once the incoming air is filtered and compressed in the MAX 30 unit, it is directed into one of the two sieve beds. As the air enters the bed, the nitrogen is adsorbed by the sieve and the oxygen passes through as product gas to the storage tank at a pressure around 20 psi (1.3 bar). Each bed produces oxygen until the sieve in that bed is saturated with nitrogen. When this occurs, the feed airflow is directed to the other bed, which continues the production process. While the second bed is producing oxygen, the first bed is releasing into the atmosphere the nitrogen it adsorbed, under very low pressure through a waste gas silencer.

From the storage tank, the oxygen product gas passes through a booster compressor designed to raise the operating pressure. Oxygen at the higher pressure passes into the booster storage tank. This storage tank serves as a reservoir for the oxygen prior to entering flow meter. A regulator maintains the oxygen output at 50 psi (3.4 bar). From the storage tank the oxygen passes through a bypass OCSI monitor where a digital display of the concentration is produced. The booster compressor will automatically de-energize when the maximum pressure is reached.

Additional information

| Weight | 150 kg |

|---|